PTFE Membrane Distillation Module

General Information

PTFE membrane distillation module is a module for membrane distillation, which is a thermally driven transport process that uses hydrophobic PTFE membranes.PTFE membrane distillation module is made of high-performance hydrophobic hollow fiber membranes.

The working principle of membrane distillation:

First, the feed liquid is heated to a certain temperature by using factory waste heat or steam, and then pumped into the membrane distillation module through the raw material pump. Membrane distillation modules are potted with hollow fiber microporous hydrophobic PTFE membranes, which have a large number of micropore. At high temperatures, the feed liquid generates a vapor pressure difference on two sides of the membrane. A large number of micropore can allow the evaporated water vapor to pass through the membrane pores, enter the other side of the membrane hollow fibers, and use the vacuum system to pump it out. After a large amount of water vapor volatilizes, the feed liquid is concentrated. The volatilized steam uses the heat pump to recover heat and returns to reheat the feed liquid to reduce the energy consumption of the entire system.

Features

Super hydrophobic PTFE membraneHigh tolerance to acid and alkali

Uniform pore sizes

Multiple options for dimensions and membrane areas

Advantages

Applicable for critical applicationsHigh separation efficiency

Adapt to different scale projects

Applications

Seawater desalinationWastewater zero discharge

Acid alkali concentration

Concentration or purification crystallization of saline solution

Concentration of aqueous solutions containing non-volatile or semi-volatile organic compounds

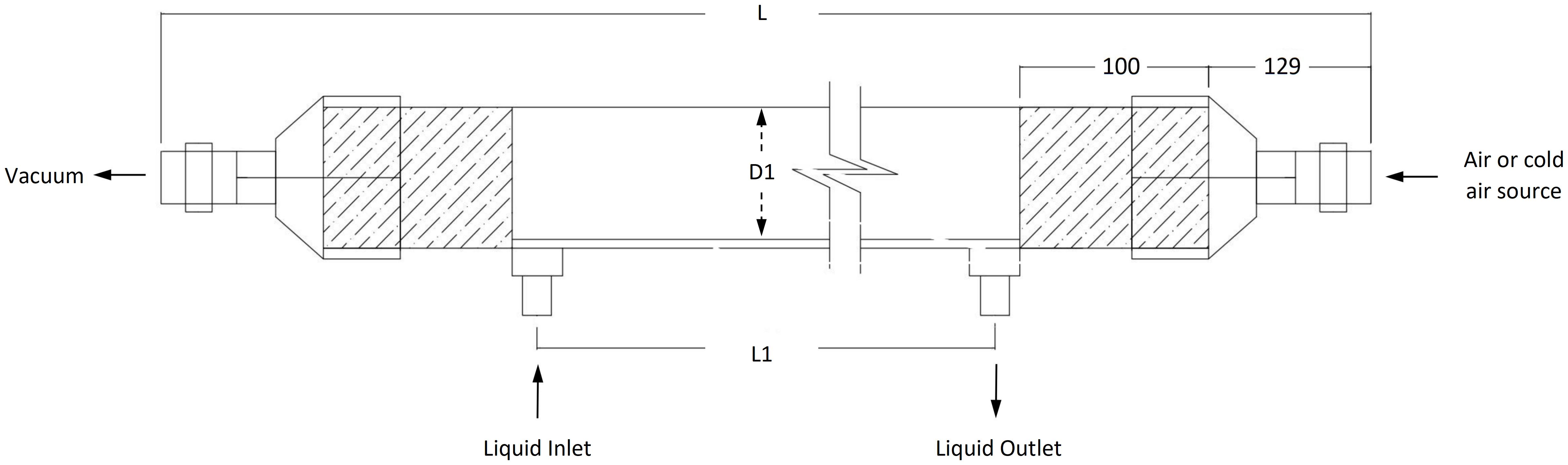

Dimensions

|

Model* |

D1 (mm/inch) |

L (mm/inch) |

L1 (mm/inch) |

Liquid port |

Vacuum port |

|

TCMD440-5 |

110/4.33 |

1,598/62.91 |

1,100/43.31 |

DN25 union |

DN25 union |

|

TCMD660-18 |

160/6.3 |

1,782/70.16 |

1,284/50.55 |

DN32 union |

DN32 union |

|

TCMD970-42 |

225/8.86 |

2,036/80.16 |

1,538/60.55 |

DN50 union |

DN50 union |

|

TCMD980-48 |

225/8.86 |

2,290/90.16 |

1,792/70.55 |

Specifications

|

Model |

TCMD440-5 |

TCMD660-18 |

TCMD970-42 |

TCMD980-48 |

|

Membrane material |

PTFE |

|||

|

Housing material |

CPVC |

|||

|

Fiber ID/OD |

0.8/1.6 mm |

|||

|

Pore size |

0.1 μm |

|||

|

Liquid flow path |

External of hollow fibers |

|||

|

Membrane area |

5 m2/54 ft2 |

18 m2/194 ft2 |

42 m2/453 ft2 |

48 m2/517 ft2 |

|

Weight |

10.9 KG/24 lbs |

25.8 KG/57 lbs |

43 KG/95 lbs |

45 KG/99 lbs |

Operating Limits

|

Working temperature |

50 - 80℃ |

|

Max. feed pressure |

0.2 MPa (29 psi) |

|

Working pH |

0 - 14 |

1. When the liquid temperature is 85°C, the safe internal and external pressure difference of the membrane hollow fibers should be less than 0.08 MPa, and the maximum pressure difference should not be greater than 0.1 MPa.

2. When used for the concentration of different materials, the feed liquid shouldn’t contain organic solvents such as alcohols, esters, hydrocarbons, ethers, oils, etc., otherwise the service life of hollow fibers will be shorter and leakage may happen.

3. A certain flow rate is required when the feed liquid flow over the outer surface of the membrane hollow fibers. Please adjust the flow rate according to the actual conditions such as the viscosity, temperature, and crystallinity of particles of the feed liquid to prevent crystallization or high surface concentration of the membrane hollow fibers from evaporation decrease.

Tanal

Tanal