TaFlux SevBore D Series

General Information

TaFlux SevBore D series ultrafiltration membrane modules are designed and manufactured as equivalents, which are used for production of process water, potable water and wastewater. Major applications are the filtration of surface water, potable water, seawater, industrial wastewater and municipal sewage. TaFlux SevBore D series ultrafiltration modules use Tanal’s SevBore fiber technology with an inside-out flow direction. SevBore fibers are naturally hydrophilic 7-bore PES hollow fibers by advanced ultrafiltration technology, which makes TaFlux SevBore D series ultrafiltration membrane modules the most robust PES (polyether sulfone) UF membrane on the market.The mode of operation is either dead-end or cross-flow (though cross flow mode is only used in certain circumstances), backwash (with filtrate only) at regular intervals and chemically enhanced backwash are required for the continuous operation.

Features

- A nominal pore size of 0.02 μm for optimal removal of particles, bacteria, and viruses

- Inside-out flow direction without air scouring

- The 3rd generation modified PES membrane fibers of 7 bores

- Typical filtrate quality SDI < 3, turbidity < 0.1 NTU

Advantages

- Extremely high mechanical strength with no fiber breakage

- High chemical tolerance

- High-quality filtrate by reliable blocking of microorganisms and viruses

- Minimum operating costs and efficient backwash

- Economical equivalent module for direct replacement for plug-and-play

Applications

- Surface water

- Potable water

- Seawater desalination

- Pre-treatment of industrial water

- Industrial wastewater

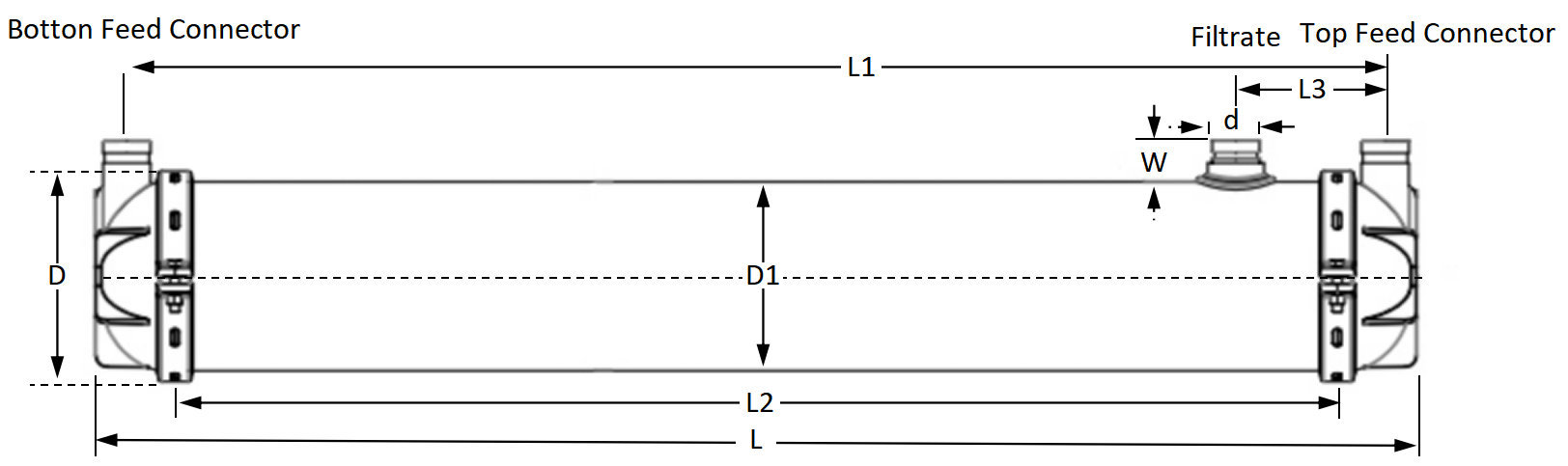

Module Dimensions

|

Model |

Total length L (mm/inch) |

Length feed connectors L1 (mm/inch) |

Length without end caps L2 (mm/inch) |

Length top feed to filtrate connector L3 (mm/inch) |

End cap diameter D (mm/inch) |

Diameter without end caps D1 (mm/inch) |

Connector length W (mm/inch) |

Feed, Filtrate connector (d)(mm/inch) |

|

TF7B0.9D-25WR |

1,180/46.46 |

1,100/43.31 |

985/38.78 |

190/7.48 |

295/11.61 |

250/10 |

55/2.17 |

2'' |

|

TF7B0.9D-30PWR |

||||||||

|

TF7B0.9D-36WR |

||||||||

|

TF7B0.9D-40WR |

1,680/66.14 |

1,600/62.99 |

1,485/58.46 |

|||||

|

TF7B0.9D-50PWR |

||||||||

|

TF7B0.9D-60WR |

Specifications

|

Model |

TF7B0.9D-25WR |

TF7B0.9D-30PWR |

TF7B0.9D-36WR |

TF7B0.9D-40WR |

TF7B0.9D-50PWR |

TF7B0.9D-60WR |

|

Effective membrane area (m²/ ft²) |

25/270 |

30/323 |

36/390 |

40/430 |

50/538 |

60/645.9 |

|

Weight (kg/lbs.) |

40/90 |

32/71 |

40/90 |

55/120 |

55/120 |

55/120 |

|

Fiber ID/OD |

0.9/4.0 mm (0.04/0.16 inch) |

|||||

|

Membrane material |

Modified PES (polyethersulfone), 7 bores |

|||||

|

Flow direction |

Inside-out |

|||||

|

Pore size |

0.02 μm |

|||||

|

Housing material |

UPVC |

|||||

|

End cap material |

UPVC |

|||||

|

Clamp material |

Stainless Steel |

|||||

|

Sealing material |

EPDM |

|||||

|

Potting material |

Epoxy resin |

|||||

|

Feed/filtrate connector |

DN50 (2 inch Victaulic) |

|||||

Operating and Cleaning Limits

|

Temperature range |

1-40℃ (34-104°F) |

|

Max.rate of temperature change (per minute) |

5℃ (9°F) |

|

Max. feed pressure |

5 bar (72.5 psi) |

|

Max. rate of pressure change (per second) |

0.5 bar (7.25 psi) |

|

Max. trans-membrane pressure |

1.5 bar (21.75 psi) |

|

Max. backwash pressure |

3 bar (43.5 psi) |

|

Filtration flux |

60-180 L/m2·h (35-105 gfd) |

|

Max. backwash/forward flush |

230-300 L/m2·h (135-175 gfd) |

|

pH-continuous operation @ 25℃ |

2 - 11 |

|

pH-CIP @ 25℃ |

1 - 13 |

|

Hypochlorite (NaOCl) for cleaning |

50 to 200 ppm |

|

Hydrogen peroxide for cleaning |

100 to 400 ppm |

Tanal

Tanal