PES Inside-Out ultrafiltration module for Pentair Norit X-Flow Xiga 40 UF membrane direct replacement equivalent

General Information

TFXG40 is manufactured as equivalent, direct replacement, alternative and retrofit to replace Pentair X-Flow Xiga 40 ultrafiltration(UF) module equivalents.

TaFlux XG series ultrafiltration membrane modules are designed and manufactured as equivalents, which are used for production of process, potable water and wastewater. Major applications are the filtration of surface water, potable water, industrial wastewater and municipal sewage. TaFlux XG series ultrafiltration modules use naturally hydrophilic PES hollow fiber ultra-filtration membrane with excellent performance.

The mode of operation is feed-and-bleed with a minor cross flow or dead-end with regular backwash (with filtrate only) and chemically enhanced backwash.

Features

-

A nominal pore size of 0.02 μm

-

Naturally hydrophilic membrane composed of a blend of polyether sulfone and polyvinylpyrrolidone

-

High performance and very good anti-fouling characteristic

-

Typical filtrate quality SDI < 3, turbidity < 0.1 NTU

-

Membrane filtration provides 99.9999% (LOG 6) reduction of bacteria (Pseudomonas diminuta) and 99.99% (LOG 4) reduction of virus (MS2 colifages) by mechanical means.

-

Suitable for horizontal installation

Advantages

-

High quality raw material

-

High thermal and chemical solvent resistance

-

High chemical tolerance for cleaning

-

Optimized design, high resistance to fouling

-

Economical

equivalent element for direct replacement in Xiga, X-line or Aquaflex systems

Applications

-

Surface water

-

Potable water

-

Seawater desalination

-

Pre-treatment of industrial water

-

Industrial wastewater

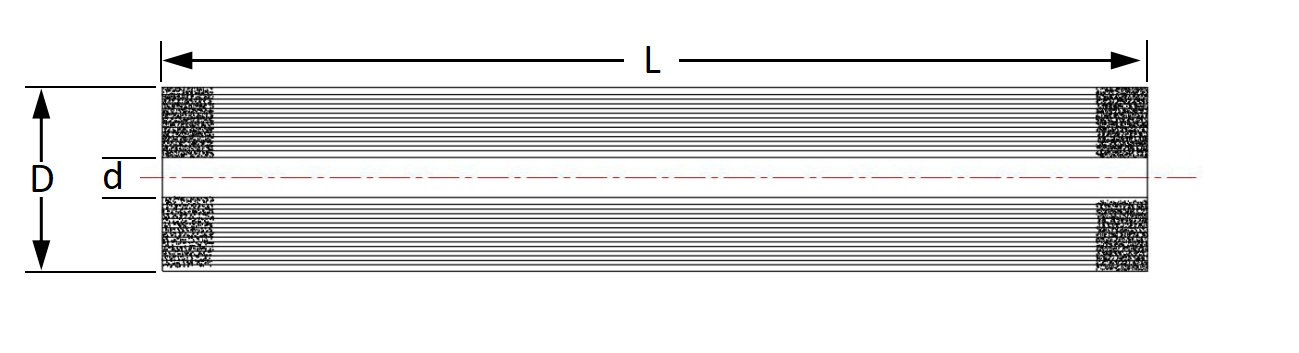

Module Dimensions

|

Model |

L (mm/inch) |

D (mm/inch) |

Filtrate connection d (mm/inch) |

|

TFXG40 |

1527.5/60.14 |

200/7.9 |

42.6/1.68 |

Specifications

Model

TFXG40

Effective

membrane area (m²/ft²)

40/430

Fiber

inner diameter (mm/inch)

0.8/0.031

Membrane

material

PES (polyethersulfone)

Housing

material

PVC

Flow

distributor material

PVC

Potting

material

Polyurethane resin

Dry

weight of membrane module

25 kg/55 lbs

Wet

weight filled with water

55 kg/121 lbs

Operating and Cleaning Limits

Max. system

pressure

300 kPa (43 psi)

Max. trans-membrane

pressure

300 kPa (43 psi)

Max. backwash pressure

300 kPa (43 psi)

Temp. range

0-40℃ (32-104°F)

pH-Continuous operation @ 25℃

2 - 12

pH-CIP @ 25℃

1 - 13

|

Model |

TFXG40 |

|

Effective membrane area (m²/ft²) |

40/430 |

|

Fiber inner diameter (mm/inch) |

0.8/0.031 |

|

Membrane material |

PES (polyethersulfone) |

|

Housing material |

PVC |

|

Flow distributor material |

PVC |

|

Potting material |

Polyurethane resin |

|

Dry weight of membrane module |

25 kg/55 lbs |

|

Wet weight filled with water |

55 kg/121 lbs |

Operating and Cleaning Limits

Max. system

pressure

300 kPa (43 psi)

Max. trans-membrane

pressure

300 kPa (43 psi)

Max. backwash pressure

300 kPa (43 psi)

Temp. range

0-40℃ (32-104°F)

pH-Continuous operation @ 25℃

2 - 12

pH-CIP @ 25℃

1 - 13

|

Max. system pressure |

300 kPa (43 psi) |

|

Max. trans-membrane pressure |

300 kPa (43 psi) |

|

Max. backwash pressure |

300 kPa (43 psi) |

|

Temp. range |

0-40℃ (32-104°F) |

|

pH-Continuous operation @ 25℃ |

2 - 12 |

|

pH-CIP @ 25℃ |

1 - 13 |

Tanal

Tanal