General Information

Features & Advantages

- Improved feed spacer to thicker channel

- Optimized design, good resistance to fouling

- Greater restorability after chemical cleaning

- Economical equivalent element for direct replacement

Applications

- Surface water

- Industrial wastewater

- Industrial process water

- Reclaimed water recycling etc.

Specifications

-

Configuration: Spiral wound element

-

Membrane Polymer: Polyamide thin-film composite

Performance

|

Element Part Number |

Membrane Active Area |

Feed Spacer |

Permeate Flow Rate* |

Stabilized Salt Rejection** |

Minimum Salt Rejection |

|

TFFR-8040HR |

400 (37.2) |

34 (0.864) |

10,500 (40) |

99.7% |

99.5% |

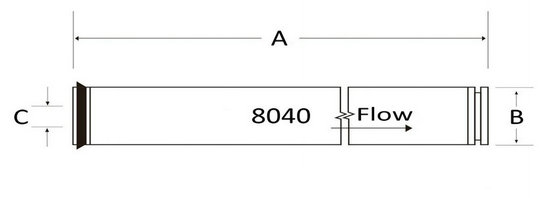

Element Dimensions

|

Length A |

Diameter B |

Permeate tube inner diameter C inch (mm) |

|

40 (1,016) |

7.9 (201) |

1.125 (28.6) |

Operating and Cleaning Limits

|

Maximum Operating Pressure |

600 psi (41 bar) |

|

Maximum Operating Temperature |

45°C (113°F) |

|

Maximum Chlorine Concentration |

0.1 ppm |

|

pH Range, Continuous |

2-11 |

|

pH Range, Cleaning |

1-13 |

|

Maximum Feed SDI (15 mins) |

5 |

|

Maximum Element Pressure Drop |

15 psi (1 bar) |

|

Maximum Feed Flow |

17 m3/h |

|

Minimum Ratio of Concentrate to Permeate Flow for Each Element |

5:1 |

Tanal

Tanal