General Information

Gas transfer membrane is a membrane that removes gasses from the liquid and makes possible the direct contact between gaseous phase and aqueous stream without dispersion.The working principle of gas transfer membrane:

Gas transfer membranes use microporous hollow fiber membrane to remove oxygen from water. In a typical operation, water flows outside the membrane hollow fibers, while inside of the hollow fibers are vacuum pumped or gas purged, or both are combined.

Gas transfer membrane provides efficient dissolved gas control in a compact design. Capable of adding gases to or removing dissolved gases (such as dissolved oxygen and carbon dioxide) and bubbles from compatible liquid streams, these gas transfer membranes utilize hollow fiber membrane technology that may help facilities around the world improve operating efficiency, performance and protect product quality.

The hydrophobically treated hollow fiber membranes have many micro pores on the surface, which allow gas molecules to pass through, but can prevent water molecules from penetrating. Under the negative pressure of vacuum or gas purging, the dissolved gas in the water outside the hollow fiber membrane moves continuously to the inside of the hollow fiber membrane through the micro pores, and is taken away by the vacuum or purging gas, so as to achieve the purpose of removing dissolved oxygen, carbon dioxide and other gases in water or other liquids. Gas transfer membranes can also be used for membrane extraction, deamination and denitrification etc.

Features

Hollow fiber membrane with bigger surface areaCompact design for normal base construction with installation

Can be installed directly on ground, no need of high position installation.

Works under normal temperature, no need of hot steam for deoxygenation.

Energy consumption comes from vacuum pump and sweep N2

Modular design, can be extended very easily.

Advantages

Higher flow rateEnergy saving by low energy consumption

High removal efficiency for dissolve oxygen, keep stable at 7 ppb of outlet water.

Small footprint to save CAPEX

Easy to install, operate and maintain for lower OPEX.

Applications

Food & beveragePharmaceuticals

Microelectronics & semiconductors

Gas separation

Inkjet printing

Hydrometallurgy

Coating

Boiler water

Water and wastewater treatment

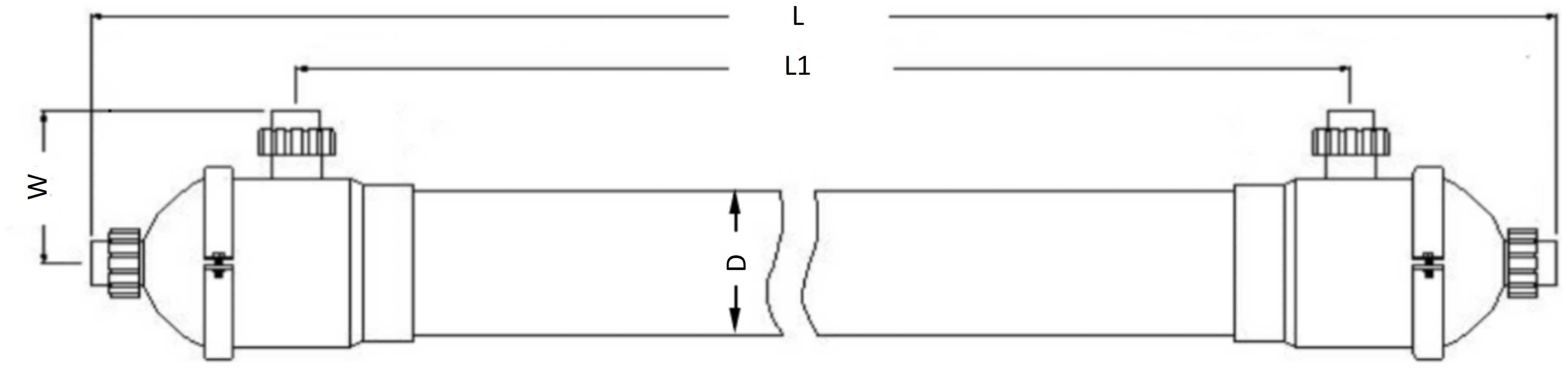

Dimensions

|

Model* |

D (mm/inch) |

L (mm/inch) |

L1 (mm/inch) |

Liquid port |

Vacuum port |

|

MCO2-6X47S |

168/6.61 |

1,205/47.44 |

860/33.86 |

DN32 Tri-clamp |

DN25 Tri-clamp |

Specifications

|

Model |

MCO2-6X47S |

|

Membrane material |

Modified PP |

|

Fiber ID/OD |

0.22 mm/0.4 mm |

|

Pore size |

0.1 μm |

|

Housing material |

SS304 |

|

Membrane area |

23 m2 |

|

Weight |

20 KG |

|

Processing capacity |

0.05 - 1.5 m3/h |

|

Standard removal rate |

75% - 95% |

Operating Limits

|

Model |

MCO2-6X47S |

|

Working temperature |

5 - 65℃ |

|

DO reachable |

< 5 ppb |

|

Max. feed pressure |

0.1 MPa (14.5 psi) |

|

Max. Trans-membrane pressure |

0.2 MPa (29 psi) |

|

Working pH |

3 - 12 |

|

Working surface tension |

≥ 65 mN/m |

1. The gas transfer membrane is only suitable for deoxidization of clean water, COD < 50 ppm, SS < 5 ppm.

2. Even if COD in water is less than 50 ppm, the surface tension may still be less than 65 mN/m, resulting in membrane infiltration. Therefore, the detection of surface tension is necessary before use.

3. The water should not contain oxidizing substances, such as hypochlorite, hydrogen peroxide, etc. ORP < 100 is required, otherwise the service life of the membrane conctactor will be affected.

4. When used for a long time, the organic and mineral substances in water will cause membrane fouling, which will affect the removal and hydrophobic properties of the membrane. It should be cleaned regularly and restored.

Tanal

Tanal