General Information

PES ultrafiltration membrane TFLQ75 is a pressurized ultrafiltration membrane module, which are designed and manufactured for the filtration of surface water, potable water and process water etc. These PES ultrafiltration membranes TFLQ75 are made of new generation PES hollow fiber membrane with high fouling resistance and hydrophilicity.PES ultrafiltration membranes TFLQ75 are applied in new systems, as well as directly connected to existing UF systems as replacements, providing high-quality filtrate by removing suspended solids, colloids, pyrogens, bacteria, viruses and other impurities to protect downstream processes.

Features

- Inside-to-outside flow direction

- New generation PES hollow fiber

- Nominal pore size of 0.02 μm

- Optimized structure for backwash

- Typical filtrate quality SDI ≤ 2.5, turbidity ≤ 0.1 NTU

Advantages

- High tolerance for feed water

- High-quality filtrate

- Less energy needed by high flux

- High backwash recovery by fouling resistance

- Longer service life by optimized structure

- Economical equivalent PES ultrafiltration membrane for direct replacement

Applications

- Surface water

- Potable water

-

Industrial process water

- Industrial wastewater

- Pre-treatment of seawater desalination

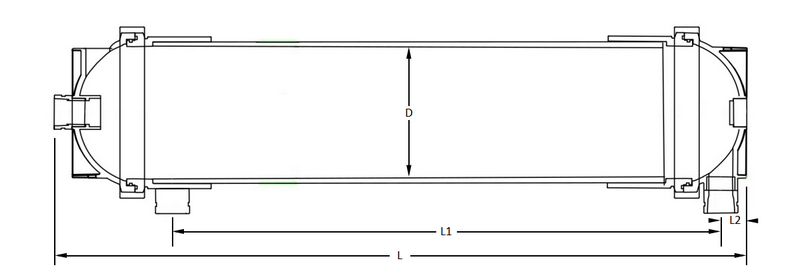

Module Dimensions

|

Model |

L* (mm/inch) |

L1* (mm/inch) |

L2* (mm/inch) |

D (mm/inch) |

|

TFLQ75 |

1,543/60.75 |

1,223/48.15 |

57/2.24 |

315/12.4 |

* Take TFLQ75-RAS666 as examples.

Specifications

|

Model |

TFLQ75 |

|

Effective membrane area |

75 m² (807 ft²) |

|

Membrane material |

PES (Polyethersulfone) |

|

Fiber ID/OD |

0.8/1.2 mm (0.03/0.05 inch) |

|

Pore size |

0.02 μm |

|

Flow direction |

Inside-out |

|

Housing material |

PVC |

|

Clamp material |

Stainless steel |

|

Potting material |

Polyurethane resin |

|

End cap sealing |

EPDM |

|

Connection port |

Variable (refer to Ordering Guide) |

|

Dry weight |

51 KG (113 lbs) |

|

Wet weight filled with water |

133 KG (293 lbs) |

Operating and Cleaning Limits

|

Type of operation |

Dead-end flow or cross flow |

|

Design flux (25°C) |

50-150 L/m2·h (29-88 gfd) |

|

Working temperature @4 bar (58 psi) |

1-40°C (34-104°F) |

|

Maximum working pressure (20°C) |

6 bar (87 psi) |

|

Maximum trans-membrane pressure |

2.5 bar (36 psi) |

|

Typical trans-membrane pressure |

0.1-0.7 bar (1.5-10 psi) |

|

Backwash flux (25°C) |

225-300 L/m2·h (133-176 gfd) |

|

Typical backwash trans-membrane pressure |

0.5-2 bar (7-30 psi) |

|

pH-Continuous operation @25°C |

2 - 12 |

|

Cleaning chemicals |

NaOH, NaClO, HCl |

|

pH-Cleaning @25°C |

1 - 13 |

|

Maximum instantaneous free chlorine concentration |

200 ppm |

|

Maximum free chlorine exposure |

200,000 ppm |

Ordering Guide

|

Module Type |

Membrane Area |

- |

Bottom Connection |

Top Connection |

Filtrate Connection |

Dimension of Bottom Connection |

Dimension of Top Connection |

Dimension of Filtrate Connection |

|||||||

|

TFLQ |

75 |

=75 m² |

- |

A |

=axial |

A |

=axial |

B |

=bent |

2 |

=Victaulic 63 mm |

2 |

=Victaulic 63 mm |

2 |

=Victaulic 63 mm |

|

|

|

|

|

R |

=radial |

R |

=radial |

D |

=double |

|

|

|

|||

|

|

|

|

|

|

|

|

|

S |

=single |

3 |

=Victaulic 73 mm |

3 |

=Victaulic 73 mm |

3 |

=Victaulic 73 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

6 |

=Victaulic 76 mm |

6 |

=Victaulic 76 mm |

6 |

=Victaulic 76 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Tanal

Tanal